Cause: 1. The nozzle is too small, and the cutting focus does not match. 2. The air pressure is too small or too large, and…

READ MORE ->

Laser Power

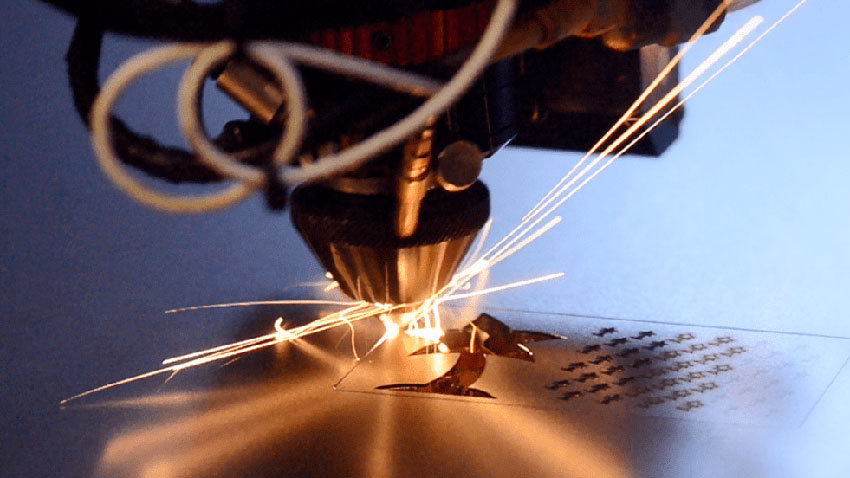

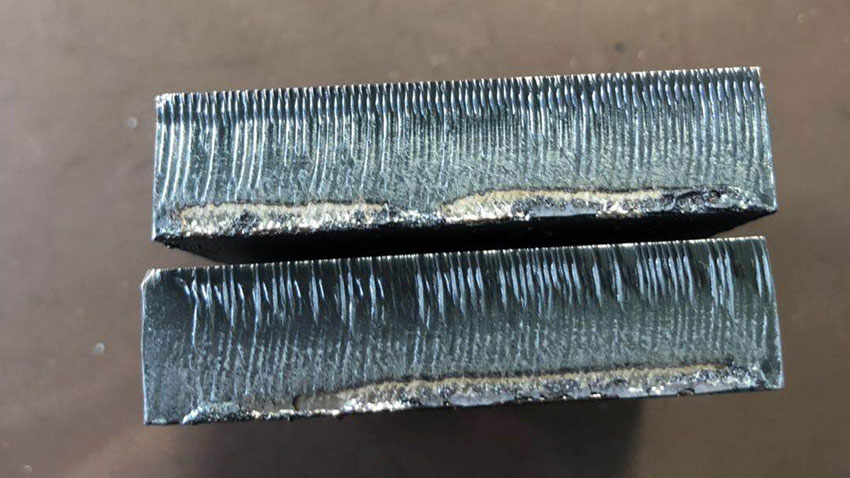

Why Are There Streaks on the Surface After Laser Cutting?

Cause: 1. The nozzle selection is wrong, and the nozzle is too large. 2. The air pressure is not set correctly. If the air pressure…

READ MORE ->

Under What Circumstances Should the Output Power of the Laser Cutting Machine Be Increased?

1. The cutting speed of laser cutting machine is too slow Increase laser output power for faster cutting. 2. Cutting materials with larger thickness Increase…

READ MORE ->

The Main Factors Affecting the Marking Speed of Laser Marker

The main factors affecting the laser marking speed are divided into two aspects: internal factors and processing workpieces. Internal factors They are laser frequency, laser spot…

READ MORE ->

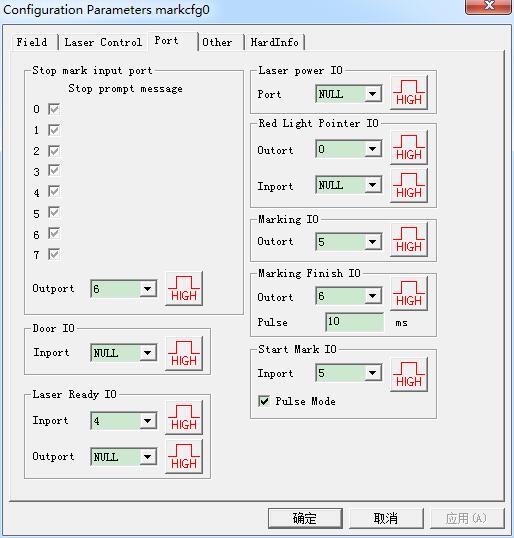

Param(F3) Configuration: Port

Stop mark input port: When in marking process, if the system detects there is a corresponding input signal, the current marking operation will be ended, and…

READ MORE ->